The Weld Tech Group company implements projects for various industries, taking into account specific requirements for installation, hygiene, safety and efficiency.

Strict sanitary and hygienic requirements (e.g., HACCP).

Need for flawless weld quality and ease of sanitary equipment processing.

Use of stainless steels and materials that comply with food safety.

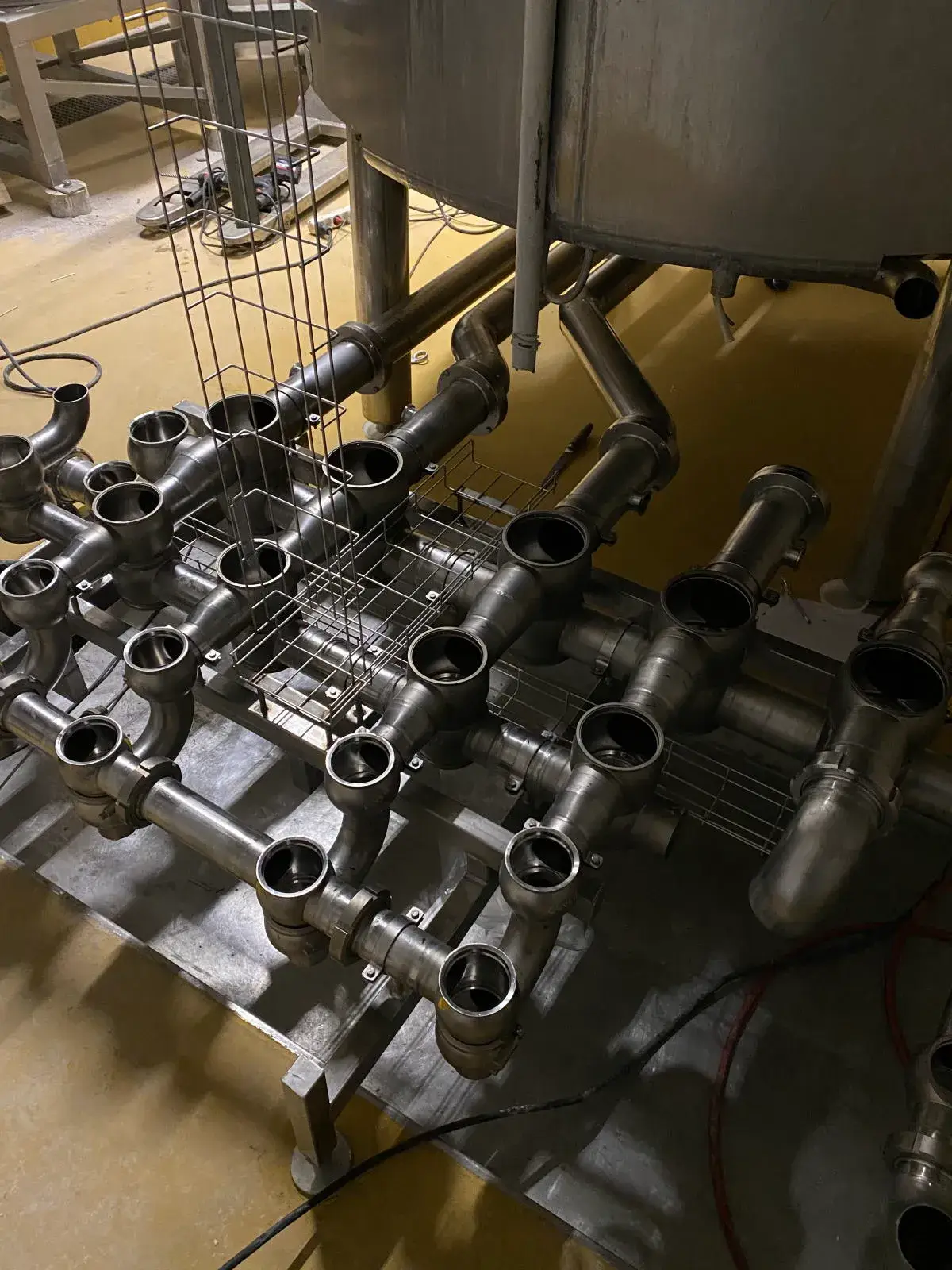

Design and installation of pipeline systems for liquid and bulk products.

Manufacturing of specialized tanks (for milk, beer, juices, etc.) considering thermal treatment or cooling.

Manufacturing of additional structures (conveyors, rollers, washing baths), adapted to high humidity and aggressive cleaning agents.

Aggressive environments (acids, alkalis, organic solvents, etc.).

Detailed requirements for tightness, corrosion resistance and personnel safety.

Need for specialized equipment for storage and processing of chemical substances.

Manufacturing of tanks and pipelines for working with aggressive chemical environments.

Durable metal structures, resistant to corrosion and temperature fluctuations.

Possibility to manufacture non-standard systems for specialized technological processes.

Strict purity requirements (GMP, FDA and others).

Full compliance with high sterility standards and prevention of cross-contamination.

Use of high-purity alloys with minimal impurity content.

Installation of pipelines and systems for storage of high-purity environments (water for injection, pharmaceutical steam).

Manufacturing of tanks with special internal surface treatment (polishing, passivation).

High-precision welding (e.g., orbital), minimizing roughness and welds that retain microorganisms.

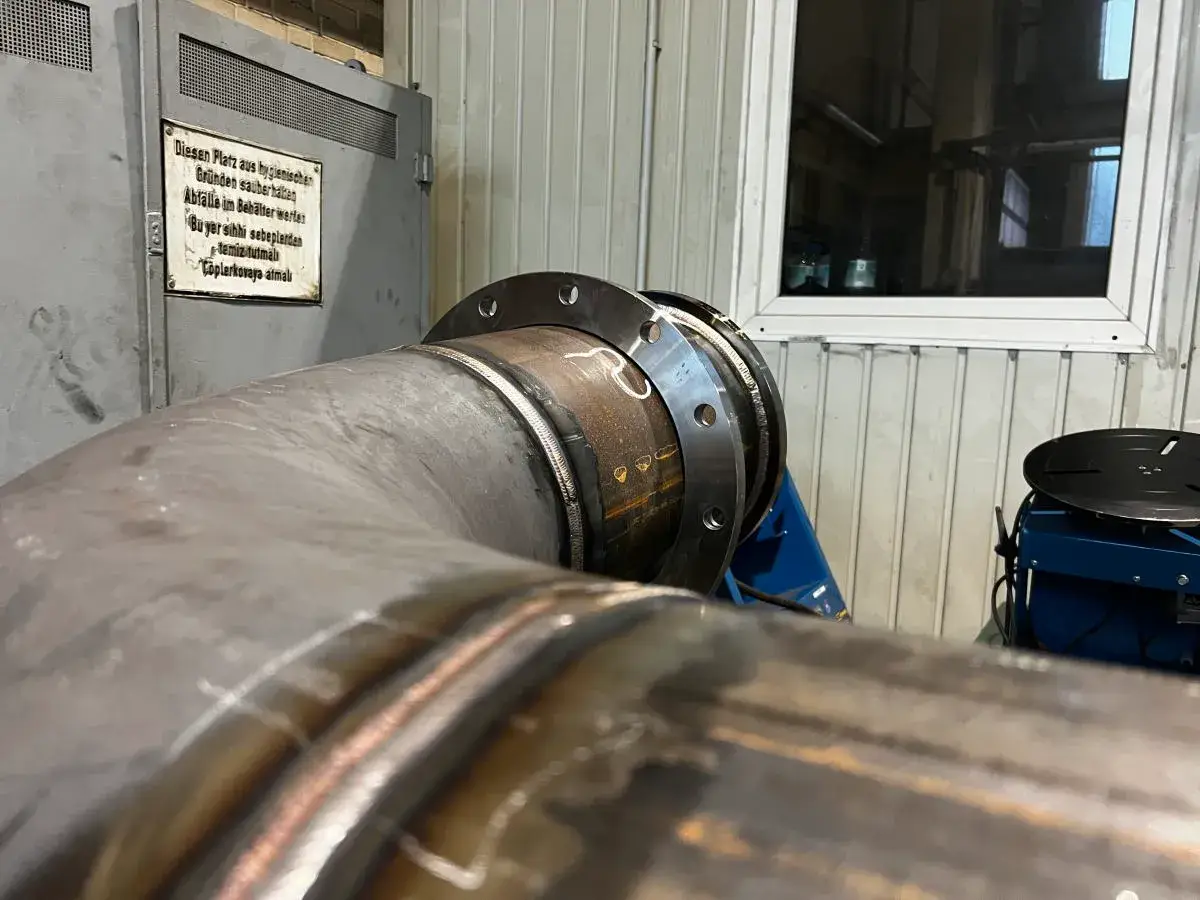

High demands for the reliability of equipment and welded joints under high temperature and pressure conditions.

Work with steam, gas, and hydraulic systems.

Strict compliance with safety regulations, as well as energy efficiency and environmental safety standards.

Installation of pipelines and metal structures for boiler rooms, turbine units, and compressor stations.

Fabrication of tanks, heat exchangers, chimneys, and other components of energy infrastructure.

Welding of structures made of alloyed, heat-resistant, and corrosion-resistant steels, including multilayer welding technology and edge preparation.

Besides key areas (food, chemical, pharmaceutical, energy), we also work with companies from:

Manufacturing and installation of components for production lines, including welding of complex metal structures.

Tanks for petroleum products, gas pipelines, corresponding fittings.